When wet painting, liquid paint is sprayed onto plastic or metal parts. Alro has state-of-the-art paint lines that automatically perform various process steps on the products.

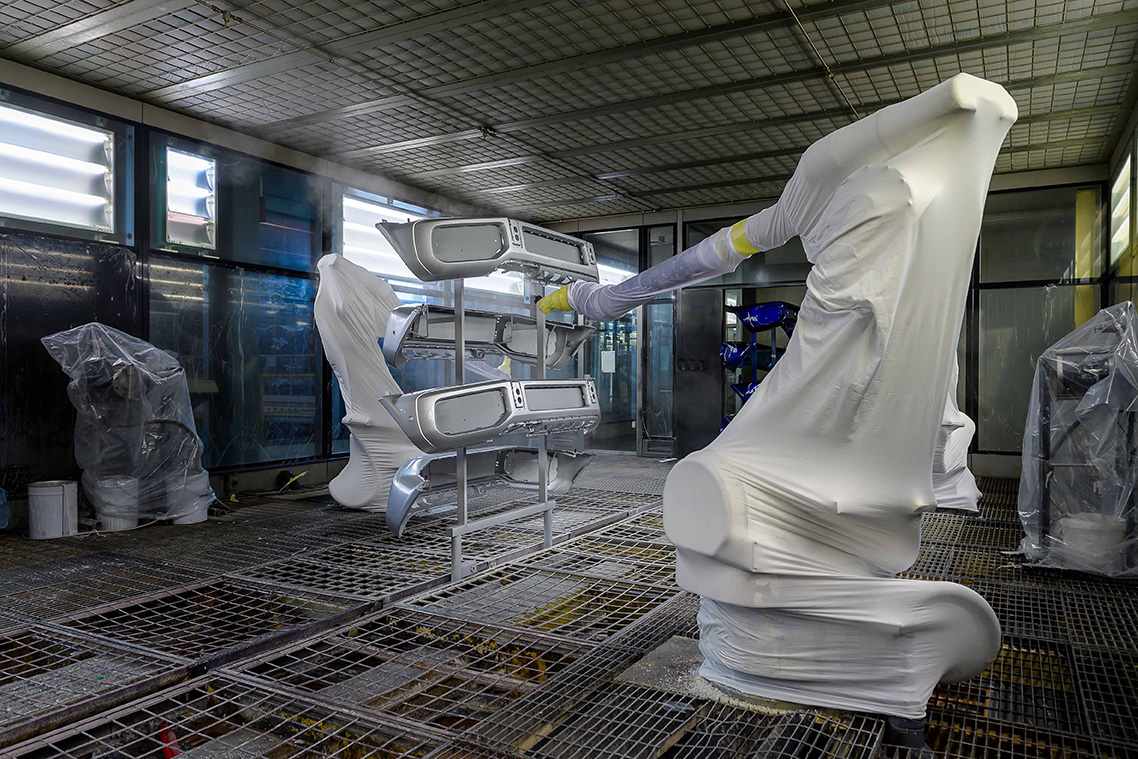

The process starts with pretreatment to ensure the products are perfectly clean. Then some plastics undergo flame treatment to improve the adhesive characteristics. Of course, we define the composition of the different coats in advance. There can be one to four coats depending on the application. The various coats are applied either manually or by robots in one or more booths. This is done with conventional or electrostatic paint guns. The paints are 1 or 2 component water or solvent based systems. Depending on the application, we choose primers, solid colours, metallic colours, coloured micas, soft coats or transparent varnishes. The combinations are countless here as well: we apply up to 2,000 different wet painting colours each year.

After the coating process, we take the products off the conveyor system, to be quality controlled and finally packaged. We are extremely careful during the packaging process, as wet painting makes the parts extremely sensitive. Curing takes about two weeks, so the surface is not yet fully cured during the packaging process. As a result, it may be compressed during packaging. That is why we always use special packaging so that your delivered products always have the high quality you expect.

Wet painting is suitable for both exterior parts and interior parts. Many metal parts or plastic objects located on the outside of a vehicle get one or more coats. This can be in the vehicle’s colours or in specific contrast colours. The vehicle’s interior is also very important, so we give several plastic products a coat of paint that gives the product both a different colour and a different feel. In addition to such special effect coats, we use soft lacquers that give the plastic surface a soft comfort feel.